Danfoss has opened a new water testing lab at its Nordborg site in Denmark — giving customers the chance to see how nozzles really perform, not just on paper, but in practice. The facility, which began operations in April 2025, allows testing under live conditions that mimic actual industrial settings.

From droplet formation to spray angle and pressure behaviour, users can now run trials that reflect how the product will behave in daily use. Applications range from humidification and dust control to adiabatic cooling, where consistency is critical.

This isn’t just about product features. It’s about giving customers confidence through evidence.

“It’s not enough to make a good product. What matters is being able to prove it performs exactly as expected,”

— Rasmus Jørgensen, Mechanical Engineer at Danfoss

Why The Lab Was Built

While many manufacturers rely on standard demos or technical brochures, Danfoss took a different path. The new water lab was designed to offer precision testing, using real system pressures and tailored configurations that match customer needs.

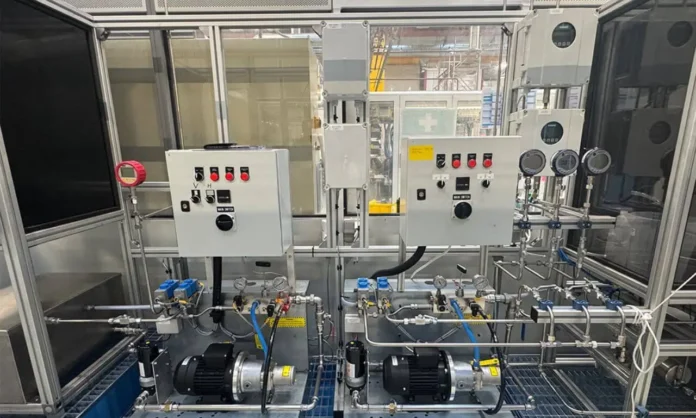

The setup includes high-spec test benches, adjustable flow settings, and sensors that track everything from mist behaviour to anti-drip performance. It’s a hands-on space, where results speak louder than claims.

Already, four customer tests have been completed at the lab, with more scheduled in the coming weeks. The goal is simple: help buyers make faster, more informed decisions based on accurate, measurable results.

“This lab lets us work side by side with customers to find exactly what works. It’s about getting the details right early, so we all save time and cost later,”

— Satish Ligade, Product Engineer at Danfoss

From Concept to Proof: What Customers Can Test

Each test session at the Danfoss water lab is fully customisable. Customers bring their specs—and the Danfoss team sets up a matching test environment. That means the data gathered is directly relevant to how the nozzle will perform in real use.

Tests can evaluate:

-

Spray coverage and droplet uniformity

-

System pressure response

-

Anti-drip behaviour under pulsed use

-

Spray angle and flow rate consistency

This level of transparency is rare in the industry. In performance-critical sectors, such as:

-

Disinfection and sanitation (where droplet size affects coverage)

-

Adiabatic cooling (where uniformity affects energy efficiency)

-

Dust and odour suppression (where angle and mist reach are key)

Being able to test before purchase means buyers reduce risk, meet compliance standards, and avoid costly trial-and-error on site.

“Seeing is believing. That’s why this lab exists. We want to show—not just say—what our nozzles can do,”

— Bart Greaves, Head of Global Sales & Marketing, Danfoss Burner Components

Competitive Advantage: Few Rivals Offer This

In a typical B2B spray component market, most suppliers provide product data sheets, not validation environments. Danfoss is now among the few with an in-house, customer-accessible test lab.

The facility doesn’t just serve current customers. It supports R&D, fast-tracks product development, and helps engineers identify design issues before mass production. That means better products and shorter lead times.

It also supports Danfoss Spray Technologies’ growth into sustainable water applications—backed by real-time insights instead of theoretical specs.

Supporting New Applications with Proven Results

Danfoss brings over 75 years of experience in simplex pressure swirl atomisation—a core principle in its nozzle design. This expertise now underpins a growing portfolio of water nozzles designed for:

-

Agriculture – for crop spraying, irrigation, and greenhouse humidity

-

HVAC and cooling – especially adiabatic systems and ventilation

-

Food processing – for clean-in-place or disinfection sprays

-

Industrial dust control – where misting systems reduce airborne particles

Each of these applications benefits from verified performance data. For customers, that means fewer installation problems, more efficient systems, and easier internal approval processes.

A Smart Investment That Builds Trust

The water lab may seem like a modest investment in physical terms—but strategically, it’s a major win.

As industrial buyers shift toward data-driven procurement, tools like this make a difference. Customers want proof. They want the confidence to move quickly, backed by numbers and test reports they can use.

And for Danfoss, the lab provides just that—at the exact moment buyers are evaluating their options.