In 2025, supermarket supply chain are smarter, faster, and more complex than ever. From farms and factories to your store shelf, every step now runs on data, robots, and real-time planning. This blog shows how today’s grocery supply chain works—and why it matters more than ever.

Key Highlights from the Blog

- Supermarket Supply Chain Overview

- Modern Chain Workflows

- 2025 Disruptions

- Emerging Trends

- Supply Chain Tech

- Private Label Strategies

- Global Case Studies

- Risk and Resilience

- Automation and Labor

- Sustainable Operations

- AI and Forecasting

- Future Outlook

What is a Supermarket Supply Chain?

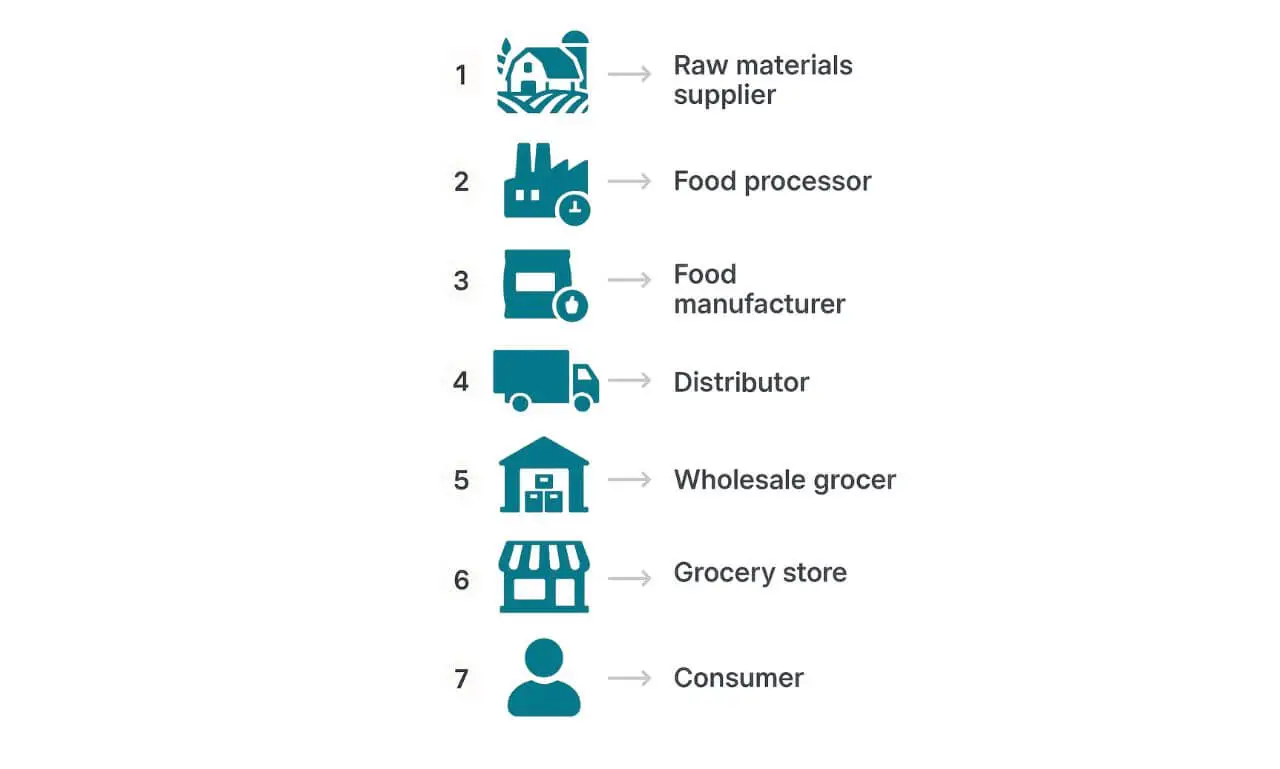

The chain that is implemented to deliver the cost of food and house hold goods to the retail shelves is the food and house hold goods supermarket supply chain. It starts with the suppliers of raw materials like farmers and manufacturers followed by processors, logistics operators and distributors.

These players will team up together to ensure that goods are stocked, moved and delivered to warehouses within stipulated time and in a secure manner. This is even more complicated by 2025 where the supply chain will be characterised by real time data, automation as well as the application of various sourcing strategies to regulate cost, quality and speed. The supermarkets rely on such chain to stock the shelves with goods and the prices down in order that the customers be contented.

Modern Chain Workflows

Automation, live visibility and cross-functional systems are a meld of systems that have been put in place in the modern supply chain supermarkets to facilitate movement of merchandize between its source of origin and the shelf. Order plans can be executed using AI forecasting because it is assumed that they will be based on patterns in sales and changes in weather. The suppliers are sent with electronic purchase orders and the shipments are prepared by the warehouse systems by use of automated sorters and robot pickers.

The supply chain in the regional distribution centers is monitored by temperature and handling of goods placed in a handling environment. The store has electronic shelves and intelligent shelves in which the restocking activities are conducted on time. With such streamlined operations, wait-time is reduced, there is less waste and retailers can respond faster to fluctuations in demand.

2025 Disruptions

By 2025, the supermarket supply chains are faced with numerous supply chain disruptions that have cast doubts on resilience and flexibility of supply chains. Cybersecurity risk has also been increasing where the ransomware attacks have seen the systems going off and products being missed out their timely delivery. The issue of geopolitical tension that has led to the new taxation scheme has impacted on how grocers have been addressing the issue of product sourcing especially, the necessity to import processed foods and fresh foods or not.

Labor shortage is a major challenge to logistics and warehousing in most of the sectors and this is stimulating more investment in automation. There is also the destabilization of harvests and transport plans due to unpredictable weather conditions and climatic events. These have heightened the need to be flexible in supply chain, have backup sources and integrate technology to run groceries without any hitches.

Emerging Trends

Many of the new trends will change the supermarket supply chain in the year 2025. The automation is gaining pace and robots and AI are now gaining the control of the sorting, picking, and stock on-demand forecasting in important distribution centers. The local and regional sourcing is increasing so as to reduce transportation time and carbon footprint.

The growth of the private-label is also compelling the retailer to devise intimate relationships with suppliers and shortened product development. Direct store delivery (DSD) has got popularity in line of the bakery, dairy and soft drinks which are the fast-moving lines. The block chain technology is also enhancing visibility especially on the perishable goods. These tendencies are signs of a paradigm shift in the grocer supply networks to speed, efficiency, and control.

Supply Chain Tech

In 2025, smart devices assist supermarkets in operating superior and faster supply-chains. AI helps determine the right amount to be stocked of the products to make sure that stores do not lack it and food is not going to waste. Transportation process of the food in order to keep the food fresh is monitored using small sensors (known as IoT).

The blockchain is some sort of an electronic book of records, which means the origins of any product. Some of the stores are even using the so called digital-twins where there is a representative of the supply chain so that trials can be carried out before the changes are enacted. All these aids in helping supermarkets to shift the products faster, without error and result in making the shoppers happy.

Private Label Strategies

Personal label is a product purchased with the brand of the store. The supermarkets are seeing the number of own label declaration increase at an accelerated rate until 2025. The new products include health products, ready meals and skincare and baby foods. They are no longer relegated to the status of being simple low cost solutions and most are quite good quality and designed well. The stores utilize the information on the shoppers to come up with their own brand of goods which the consumers want.

This enables them to control prices and supply more. Protection of profit during price increase of the big brands by the private label is also enabled. Supermarkets have come to understand the difference between the potential of developing there own brand by making use of the concept of private label as an intelligent way of differentiating themselves, and the need to reduce any cost and create a substance of belief in the minds of the shoppers.

Global Case Studies

The supply chains in the 2025 supermarkets are already transforming the contour of efficiency and resiliency across the globe. To ensure that its equities throughout the United States of America can make deliveries within the country on the same day, Walmart has put micro fiction centres around major towns so that it makes delivery on the same day at a cheap last missile cost. Target is utilizing AI-driven demand forecasting in over 85 percent of the grocery SKU flow to reduce almost 30 percent of inventory out-of-stocks in stores. In Germany, REWE has been able to make a series of networks with the local sources to them and now the source procures over 40 percent of all fresh produce within 150 kilometers and minimizing the carbon footprint and the distance of transportation.

French Carrefour even provided blockchain tracking of its lines of meat and sea food products mentioning about the origin of every product up to the farm and being able to react to food safety and transparency requirements. Meanwhile in Australia, Coles had implemented its distribution centre technology by introducing cold chain systems that are equipped with the incorporation of IoT to keep the temperature control at 98 percent accuracy which has greatly reduced the amount of spoilage. These case studies prove the meanings of regional focus, use of smart tech, and city-level involvement of the supplier, which is introducing a change in the conditions of supermarket operations worldwide (2025).

Risk and Resilience

In 2025, the supply chains of supermarkets experience a growing number of threats: cyberattacks and climate events, as well as geopolitical shocks, which are accompanied by a shortage of raw materials. The major players in retail are getting resilience so that they remain secure. Control towers are now being utilized by many; these are central dashboards where the companies have sight of the activities in real-time in the fields of sourcing, inventory, and logistics. Such systems will warn teams in advance in case of disruptions.

Retailers also construct multi-sourcing mechanisms where they include back up suppliers in other areas to ensure they do not over rely. Smart sensors are used to strengthen the cold storage chains and preserve perishable items in the case of outages. Also, the supermarket is training people within the organization to deal with both local and international emergencies at a fast rate. The aspiration is obvious: ensure that the supply chain is shock-proof and recovers rapidly without causing a diminished experience to the customers.

Automation and Labor

In 2025 an automated supply chain is redefining the operation of supermarkets. Retailers introduce robots, AI and other smart systems to automate jobs which used to be a human task. Robots are used in warehouses as automated sorters and robotic pickers that transport goods quickly and with minimal oversights. Use of electronic shelf labels and AI scanners in stores minimizes use of manual stock checks. Meanwhile, the issue of labor shortage (particularly, in logistics and fulfillment) is a significant problem.

As a way of adapting, supermarkets are based on automation to assist the workers instead of replacing them. As an example, co-bots (collaborative robots) help personnel that engage in heavy lifting or repetitive work. Chains are also providing employees with fresh training on the management and maintenance of digital systems. The interplay of humans and intelligent machines is assisting the retailers in getting faster, economical, and more reliable in their supply chain.

Sustainable Operations

The supply chain in the supermarket aims at promoting sustainability by minimizing the effect on the environment. Again in 2025 retailers are focusing on sustainable processes at all levels. Most of them are teaming up with local suppliers to reduce transport distances that reduce carbon emissions. Diesel fleets are being phased out to electric delivery vehicles and other types of fuel. The cold chain replaces power consuming refrigeration with energy efficient refrigerators.

Other groceries also deal directly with growers practicing regenerative farming and enhancing the health and biodiversity of the soil. Packaging too is evolving and there has been a transition to packaging that are made out of compost and containers that are to be reused in store brands. Such sustainable practices can not only keep the planet safe but are also an attraction to consumers, as they demand sustainable procurement, as well as transparency on the way their food ends up on the shelf.

AI and Forecasting

AI and prediction is revolutionizing the supply chains of supermarkets in the future of 2025. Artificial intelligence is now being used by retailers in order to forecast that demand a lot better, so that they only stock a sufficient amount of individual product. Such systems evaluate sale appearance, temperature, holidays and regional occurences to predict what will be purchased by individual shoppers.

An example would be that AI can forecast a rise in the sales of soft drinks during heatwaves or more goods like baking would be required before a holiday. This enhances stock and minimizes over stock wastage. Dynamic pricing using AI to alter the price of products in real time according to shelf life or pricing by competitors is also an element of some chains. These tools ensure retailers of grocery make quicker decisions based on data which leads to increased profits and customer satisfaction.

Future Outlook

The supermarket supply chains should be quick, smart and flexible in future. The retailers will continue investing on the automation, sourcing, and real-time visibility in the new years to come. This will see more stores being made hybrid (half store, half warehouse) to minimize on fulfillment of online orders. This will also make the supply chain more intelligent since the teams will have an improved capacity to detect risks early and make plans.

This will result in an increase of collaboration with the suppliers in the region and this will make them stronger to face shocks in the world. Sustainability will also be in the priorities and there will be shorter emissions and less waste packaging in the delivery fleets. The purpose of the task is not difficult to understand: to have the supply chain that will be capable of quick response, to perpetuate the low expense and keep the shelves loaded regardless of the problems that may emerge.

Futureproof Innovations

Areas of innovations of the supermarket supply chain in the future are agility, automation and adaptability. The mini hubs are found in the retail stores as the retailers experiment on how to increase online shipments without disrupting the custom of the day. The supply networks are able to be modelled virtually (also referred to as digital twins) and allow planners to run scenarios and make decisions with regard to changes but may not need to effect them.

Temperature tracking and monitoring of movement are being carried out on long journeys by making use of apt pallets which are intelligent and fitted with device sensors. The independent delivery cars and drone tests are also under trials among the retailers in the last-mile drop-offs. Concerning the data, the chain supply is being converted into API based supply in which data is being instantly presented among the suppliers, the warehouses and the store. The innovations are not being experimental but are the foundations of a supply chain that could stand on its feet, even in the not-so-certain times.

Supply Chain by Category

The requirements of the products of the supply chains are also varied and are varied in 2025 too. The case with fresh produce is just the same, where speed and freshness are the deciding factors: There is often the case that when it comes to fruits and vegetables that they are put, and directly in the store, without going to a refrigerated house and a long-distance transportation. Commodities like snacks and cereals come in a package, hence will follow a longer path due to manufacturing, warehousing, and distribution at the national level.

Such raw materials as dairy and meat rely on the cold division of logistics where the sensors are utilized to track the temperature data to prevent its loss. Household and non-perishable focus on volumes, price-performance and storage in the long term. With this awareness of the differences, the retailers are able to make perfect adjustments in inventory, reduce wastage and provide the product at the right time and in the right quantity.

Final Summary

By 2025, the supply chain of the supermarket is not merely a support tool anymore it is a strategic asset. Technology, consumer requirements, and international hazards are redefining every touchpoint such as sourcing and processing, distribution and retail. To be quicker and smarter, retailers are spending in automation, AI, sustainability and local sourcing. Pricing is also spreading the control of supply and brand capacity because of the private label strategies.

International practices of leading nations demonstrate that efficiency and resilience are stimulated by innovation. With increased complexity, the supply chains are becoming smarter. In the case of supermarkets as well as in the case of the FMCG companies to be able to be perfect in the chain is about having a competitive advantage based on cost, speed, trust and growth.